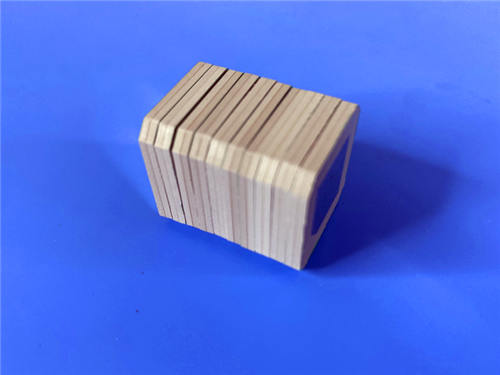

6-Layer CuClad 217 RF PCB with 3.5mm Thick Core and ENIG Finish

1.Product Introduction: High-Performance PTFE Composite

Rogers CuClad 217 represents a premium cross-plied, woven fiberglass reinforced PTFE composite laminate, engineered to deliver the industry's lowest dielectric constant (Dk=2.17/2.20) among fiberglass-PTFE materials. This 6-layer construction utilizes a unique alternating ply orientation (90° fiberglass weave) combined with high PTFE content to achieve exceptional electrical isotropy and signal integrity for mission-critical RF applications. The material's optimized fiberglass/PTFE ratio enables faster signal propagation and superior signal-to-noise ratios compared to conventional PTFE laminates.

2.Key Material Properties

Ultra-Low Dielectric Constant: 2.17/2.20 @10GHz/1MHz

Minimal Signal Loss: 0.0009 dissipation factor @10GHz

Environmental Stability: 0.02% moisture absorption

Mechanical Reliability: 14 lbs/in peel strength

Space-Qualified: TML 0.01%, CVCM 0.01% outgassing

Thermal Performance: -55°C to +150°C operational range

3.PCB Construction Details

| Base Material | CuClad 217 / RF-27 Prepreg |

| Layer Count | 6-Layer |

| Board Dimensions | 68.45mm × 97.18mm (±0.15mm) |

| Minimum Trace/Space | 5/7 mils |

| Minimum Hole Size | 0.4mm |

| Via Configuration | L1-L4 Blind Vias + Through-hole |

| Finished Thickness | 3.5mm |

| Copper Weight | 1oz (35μm) all layers |

| Via Plating Thickness | 20μm |

| Surface Finish | Immersion Gold (ENIG) |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | Green |

| Bottom Solder Mask | None |

| Electrical Testing | 100% tested prior to shipment |

4.PCB Stackup:

Copper layer 1 - 35 μm

Rogers CuClad 217 Core - 1.575 mm (62mil)

Copper layer 2 - 35 μm

Bonding ply - RF-27 -0.05mm

Copper layer 3 - 35 μm

Rogers CuClad 217 Core - 0.787 mm (31mil)

Copper layer 4 - 35 μm

Bonding ply - RF-27 -0.05mm

Copper layer 5 - 35 μm

Rogers CuClad 217 Core - 0.787 mm (31mil)

Copper layer 6 - 35 μm

5.Board Statistics

Components: 31

Total Pads: 143

Thru Hole Pads: 116

Top SMT Pads: 27

Bottom SMT Pads: 0

Vias: 39

Nets: 2

6.Manufacturing & Quality Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class 2

Availability: Worldwide shipping

7.Technical Advantages

Cross-Plied Construction: 90° alternating weave for uniform Dk

High PTFE Content: Lowest loss among fiberglass-PTFE laminates

Blind Via Capability: L1-L4 microvia integration

Space-Qualified: Meets NASA outgassing standards

Design Flexibility: Supports wider traces for reduced insertion loss

8.Target Applications

Radars

Electronic Countermeasures

Electronic Support Measures

Microwave Components (LNAs, filters, couplers, etc.)